Z Bucket Elevator For Attapulgite

Attapulgite

Attapulgite clay is a mixture of clay and non-clay minerals with its primary clay mineral being Palygorskite, a hydrous magnesium aluminosilicate. Used in various applications, attapulgite clay products serve as thixotropic rheology modifiers, low-shear thickeners, anti-settling agents, and binding agents.

Processing Technology

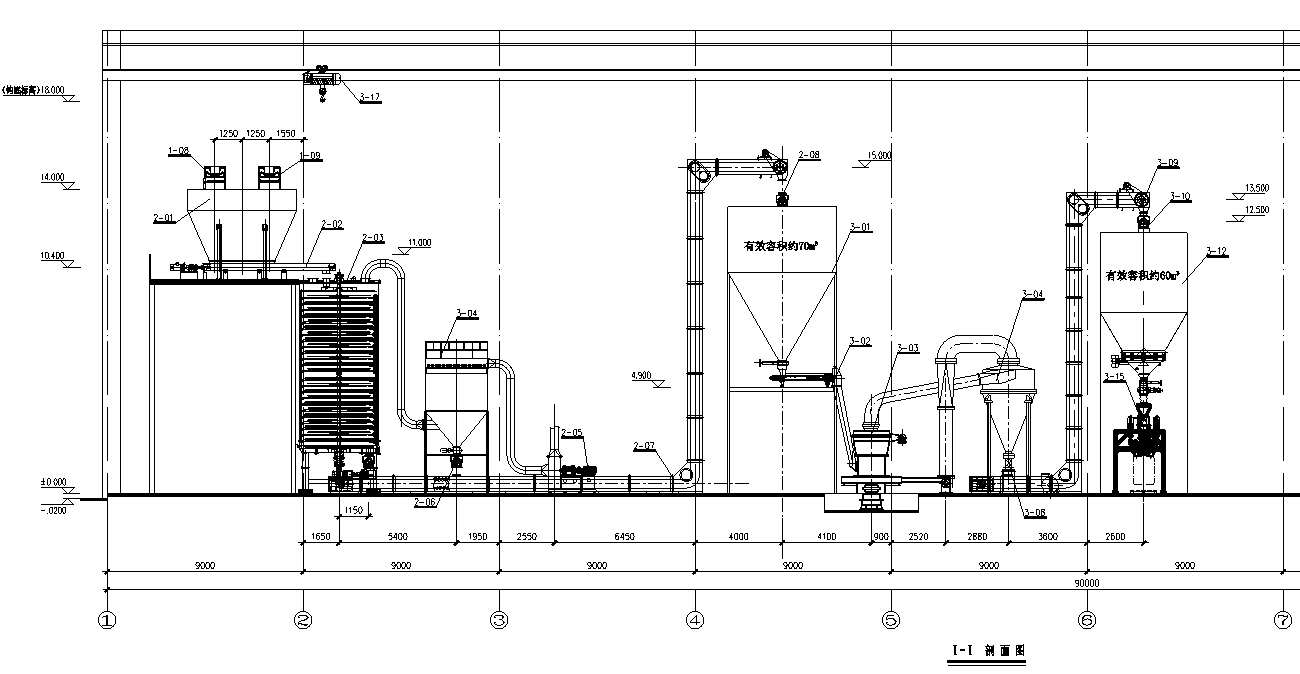

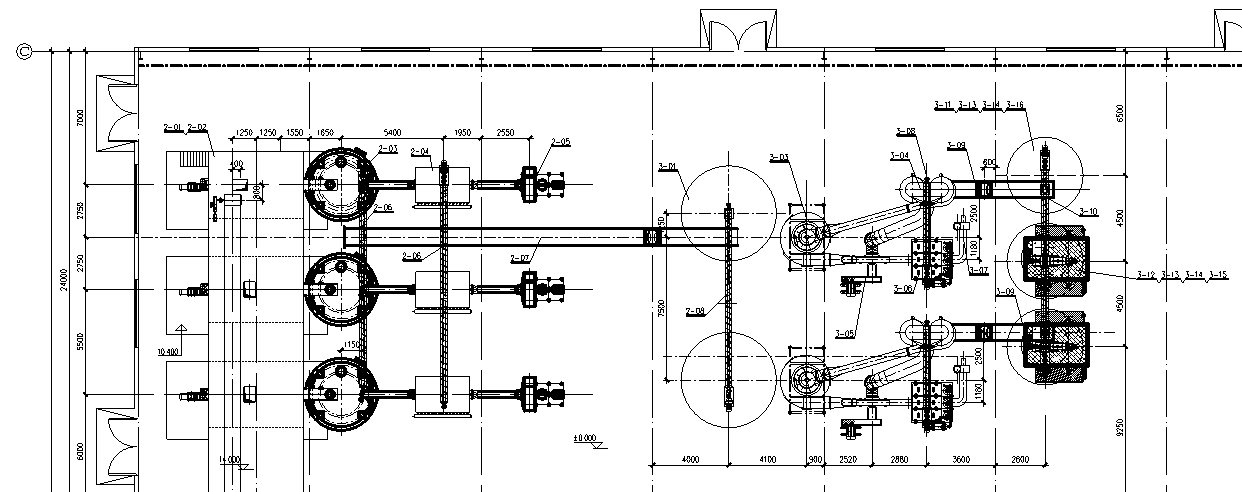

The original bulk material is first crushed by a crusher. After the material is crushed to the required particle size, the material is sent to the storage hopper by the elevator, and then the material is evenly and continuously sent into the main machine room through the vibrating feeder. Due to the centrifugal force during rotation, the grinding roller swings outward and is pressed tightly against the grinding machine. Grinding ring, the blade scoops up the material and sends it between the roller and the ring, and the purpose of crushing is achieved due to the rolling of the grinding roller. The fine powder after grinding the material is brought into the analysis machine for sorting with the circulating air of the blower. The material that is too fine and coarse falls back to be reground, and the qualified fine powder enters the finished product cyclone powder collector with the air flow and is discharged through the powder outlet pipe, that is, for the finished product.

Classification And Application

Common attapulgite mineral types include the following: (1) attapulgite type; (2) montmorillonite type; (3) attapulgite-montmorillonite type; (4)dolomite-attapulgite type; (5) Dolomite + attapulgite - montmorillonite type; (6) Opal-attapulgite-dolomite type. To obtain an ideal pure attapulgite sample, only by selecting attapulgite-type ores can we achieve our goal. The ore is distributed in the middle of the attapulgite deposit ore layer. The attapulgite content is greater than 80%, containing a small amount of quartz, dolomite, amorphous opal, and almost no montmorillonite due to the special physical and chemical properties of attapulgite clay, and process performance, making it widely used in petroleum, chemical industry, building materials, papermaking, medicine, agriculture, etc. At present, the largest users are coatings, drilling mud, and edible oil decolorization.

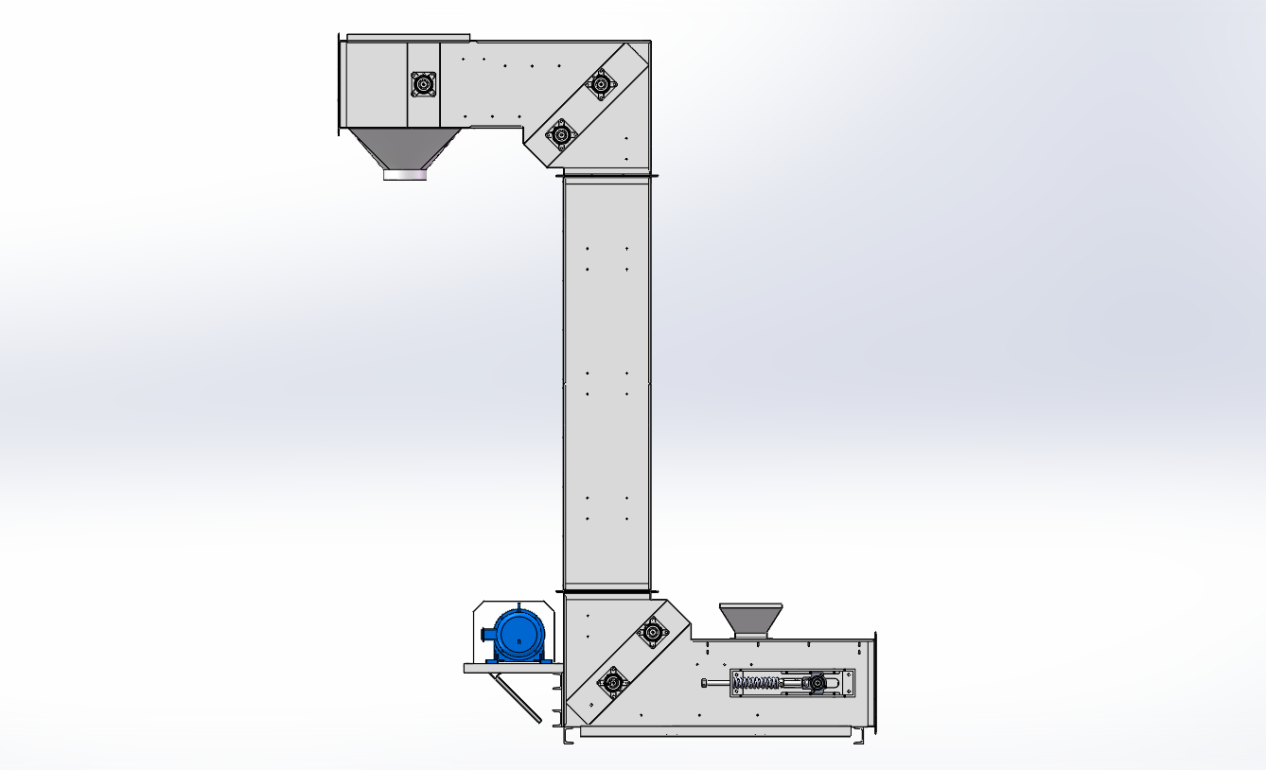

Application And Function Of Pendulum Bucket Elevators

Pendulum bucket elevators are used for very gentle vertical conveying of all kinds of powder and granular product. They are the most suitable conveyors. They can also manage big horizontal distances, thus being able to replace the combination of belt conveyor and normal bucket elevator.

Advantages

• Gentle conveying

• Combination of horizontal and vertical transport

• low energy demand

• quiet running

• low maintenance demand

• flexibility in installation

Customer’S Requirement

| No. | Name | Specifications |

| 1 | Z bucket elevator | Model-7L |

| 2 | Conveying material | Attapulgite

Bulk density is around 0.6m³/t |

| 3 | Granular size | About 5mm flakes |

| 4 | Conveying capacity | About 14m³/h |

| 5 | Water content | 12-15% |

| 6 | Conveying height | 15m |

| 7 | Horizontal conveying distance | 19m |

| 8 | Inlet and outlet | Two inlets, one outlet |

| 9 | Material of construction | All carbon steel |

Photos Of Finished Equipment

Delivery Photo