We would like to introduce parts of our Z bucket elevator, and some features of our Z bucket elevator. Compared with normal bucket elevator, it really has many advantages, a great step on raw material conveying.

INLET

Our Z bucket elevator is flexible in terms of the number of inlets.

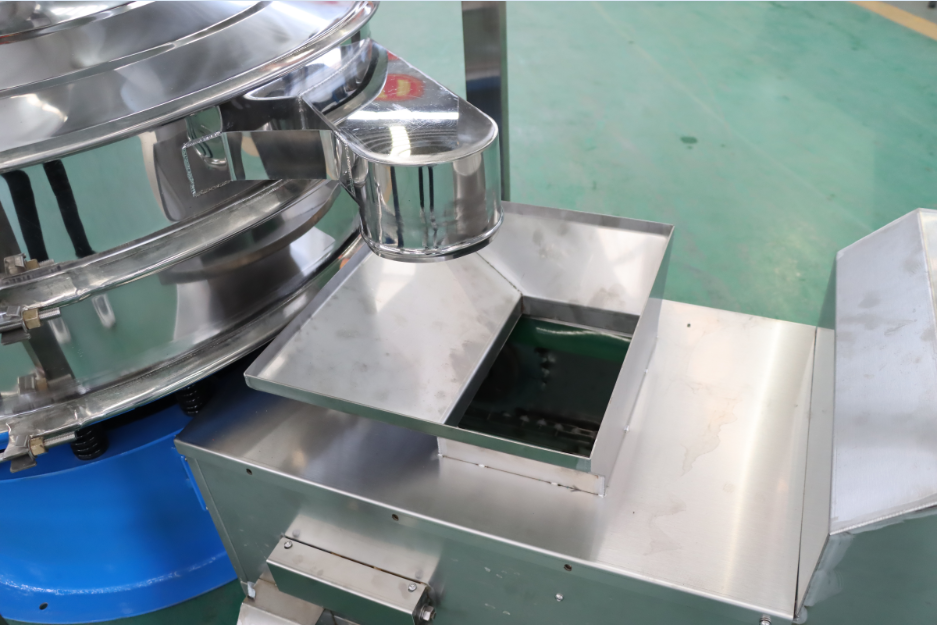

Equal and constant filling of the buckets is highly important for a good operation. This can either be ensured by a vibratory feeder or by means of the foregoing machine which can, for instance, be a screening machine with adjustable feeding system, thus the product reaches our Z bucket elevator in a well dosed stream already. In such a case, a simple flange inlet is sufficient. Due to the overlapping of buckets as well as cover-matting in the inlet section,product loss is prevented.

CHAIN AND BUCKETS

The high-tensile, chromated chain grants a long lifetime. Plastic buckets reduce the necessary drive power and at the same time treat the product to be conveyed very gently. On demand, also antistatic buckets can be offered as an option.

Regarding the chain, we also have stainless steel and carbon steel for your options.

For buckets, ABS, carbon steel and stainless steel for your options.

OUTLET

The number of outlets on our Z bucket elevator is flexible. One outlet is always fixed, while additional ones are either actuated by hand or pneumatically by the central plant control panel. No matter how the outlet is actuated, the function is always the same: The bucket reaches a crank which is mounted on the side wall of the outlet section. When the cam mounted on the side of each bucket runs over this crank, the bucket is tilted. This gentle way of tilting prevents the product from getting any hard knocks in the outlet zone, whereas a normal bucket elevator throws out the product into the outlet parable at comparable high speed. The possibility of several outlets further optimises the flexibility of this conveyor and therefore of customer's plant

LOW MAINTENANCE

Only high quality components needing little maintenance are used throughout. All models have easy to remove inspection covers and a conveniently located inspection window. Drawers are provided underneath the horizontal sections to facilitate easy cleaning. The inside walls are smooth, thereby preventing dust buildup. All bearings are mounted outside for easy access. The buckets have a quick release mechanism to facilitate fast installation or removal of buckets. All Bucket Elevators are equipped with an automatic chain tensioning device and built-in overload protection. A VFD is required for proper operation.

Our Z Bucket Elevators combine vertical and horizontal transportation of Powder and Grain Food & Industrial bulk materials in one integral unit. They are of the totally enclosed pivoting bucket type and can have multiple inlets and outlets.

GENTLE HANDLING

Our Elevators are designed for gentle handling and are well suited for a broad range of bulk products. Especially in the food, agriculture, and other industries. The buckets are overlapping at the inlets to prevent spillage and can be selectively tipped at the outlets.

MODULAR DESIGN

Our Bucket Elevator modular design allows us to customize with ease and makes our bucket elevators easy to install and modify. The most common configurations are the C and Z configurations There are different size of buckets for variable capacity expectations.

Post time: Feb-21-2023