If you are new to our Z bucket elevator, you must be confused that how to install such a big equipment after received it. Don't worry, firstly, we will be always with you to guide you how to install it; secondly, here is some ides to share with you to install the bucket elevator soonest.

1.Check whether the size of each part of the chassis is consistent with the length of the purchased equipment to determine the location of the installation of various parts.

2.Check the various parts of the box sprocket rotation is flexible to ensure the sprocket rotation flexibility without any resistance. For the active sprocket, due to the reducer connected you need to release the torque limiter on the bolt then it can be rotated.

3.Before installation, make sure that the foundation is strong enough and the ground is flat. If there is an uneven place,please adjust the height of the various positions by the bottom adjustable feet to ensure that the box is in a horizontal state.

4.After the installation of the box is complete, please check its overall straightness, if correct then check whether the location of the relevant equipment is correct, if it is not correct place please correct, if no problem and then the next step.

5.For conveyors with a high height or long length, it is required to steady the box in the appropriate position with the adjacent building, steel structure or optional welding bracket to ensure that the conveyor has good stability, can not have shaking , Swing and so on.

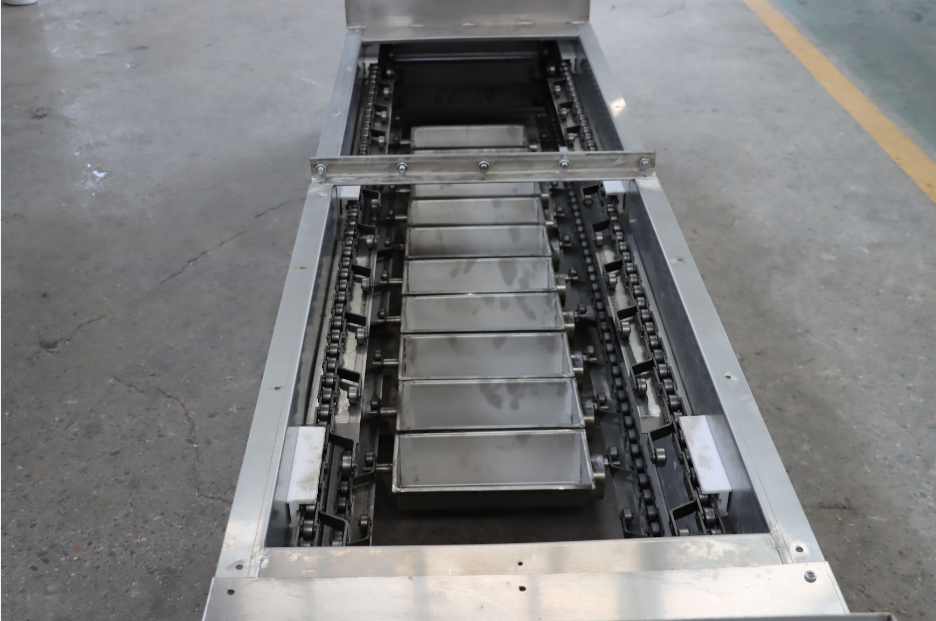

6.When begin to install the chain, firstly install the elastic tensioner unscrew at the shortest position and confirm the length of the chain and the required length is the same. For a short chain our factory will connect it before sending, for a long chain it need for field docking, docking method is the same as ordinary chain. When docking, note that the circular end of the chain of the union is in the same direction as the running direction, and the open end is prevented from falling off during the operation. To ensure that the length of the chain on both sides of the same, according to the installation of the installation of the conveyor, the interface after the chain will be tightened, not too tight, ready for the installation of hopper.

7.According to the direction of the conveyor chain to install the hopper correctly, pay attention to the part of the hopper need to install the direction of installation errors will cause damage to the hopper, if you do not know the installation please contact with the manufacturer to confirm. In the case of chain loose , the chain to the outside of the box to stay, the chain pin and the hopper at both ends of the corresponding hole can be inserted. Install a hopper at a distance from each other and the interval is 127mm (2.0 liter lift). Chain turn, install the bucket until all the correct installation is complete, the installation of a shorter conveyor can manually rotate the chain, for a longer need to connect the motor to install the hopper.

8.After the hopper is installed safely, the spring tensioner can tighten the chain to ensure proper tightening, not too loose or too tight. Observe whether the length of the two chains consistent, check whether the hopper axis with the box into 90 degrees, such as the length of the chain is inconsistent, please adjust again until the chain on both sides the same, otherwise there will run poor, phenomenon.

9.check all parts of the bolts whether are fastened, if loose please tighten, confirm the correct after the next step.

10.Check the reducer in the oil is sufficient, usually in the factory have been added if the oil is not enough please add enough oil. Pay attention to change the oil cap cover into a breathable lid to avoid damaging to the reducer as the heat.

11.Tighten the tightening limiter on the fixed bolt, turn on the power switch, the device began to run empty. Within 2 hours the overall operation is smooth, hopper flip normal, check the bearings, motors, reducer, (No more than 30 ℃), check the chain length of the operation, whether the hopper is flexible, unloading is clean, whether there are other failures, it can be feeding material at requirement capacity.

Post time: Nov-21-2022